When products fly off the shelves at an impressive speed and a short shelf life is a norm, efficient inventory management becomes the linchpin of a successful operation. This is especially true for the Fast-Moving Consumer Goods (FMCG) sector, bustling with rapid turnover and thin margins.

Yet, as essential as it is, managing inventory in the FMCG realm isn’t a walk in the park.

For starters, FMCG businesses often grapple with the daunting spectres of overstocking and stockouts. Overstocking, on the one hand, leads to locked capital and the risk of perishables going to waste.

Stockouts, on the other, can damage the brand’s reputation and result in lost sales. These issues, compounded by the inherent perishability of many FMCG products, can erode profitability and strain resources.

But as the adage goes, every problem contains the seeds of its solution. In the case of FMCG inventory challenges, the solution lies in harnessing the power of automated inventory management software.

As we journey through this blog, we’ll explore how these modern systems are tailoring their capabilities to address the specific pain points of the FMCG sector.

What is the FMCG Landscape and its Inventory Challenges?

The FMCG sector is aptly named, with its cornerstone being the “fast-moving” nature of the products it encompasses. This rapidity brings forth both opportunities and challenges, particularly when it comes to inventory management.

The Speed of Goods: Is it a Double-Edged Sword?

In the world of FMCG, products don’t linger on shelves for long. This brisk movement is both a boon and a bane.

On the positive side, high turnover indicates strong consumer demand, ensuring continuous cash flow and reduced storage costs. However, the flip side of this velocity is the constant pressure on businesses to replenish stock efficiently, making inventory management a high-stakes game.

Any misstep, like underestimating demand or over-purchasing, can lead to significant financial setbacks.

Perishability: Why is it a Race Against Time?

One of the most defining and challenging features of FMCG products is their perishability. Be it fresh produce, dairy items, or beauty products with organic ingredients, many items have a limited shelf life.

This means businesses are perennially racing against time. Stale or expired products don’t just represent financial losses but can also tarnish a brand’s reputation.

The criticality of real-time tracking in inventory management software becomes evident here, allowing businesses to stay ahead of the curve and prevent wastage.

Seasonality: Can you Predict the Unpredictable?

The FMCG sector is heavily influenced by seasonal variations. Festive periods might witness a spike in certain products, while others might see heightened demand during specific seasons.

For instance, sunscreens might see a surge in summer, while hot cocoa could be the rage in winter. Without a robust demand forecasting feature in place, businesses are left in the lurch, often caught off guard by sudden demand fluctuations.

This unpredictability, inherent to FMCG, demands advanced automated inventory management software equipped with predictive analytics.

High Turnover Rates: How Supply and Demand is a Balancing Act?

Another inherent characteristic of the FMCG industry is its high turnover rates. Products are continually being sold, restocked, and sold again.

This constant churn requires businesses to strike a delicate balance. On one hand, they need to ensure there’s enough stock to meet the ever-present demand.

But that also means avoiding overstocking which could lead to perishables going to waste or tying up capital in slow-moving goods.

What is the Need for Automated Inventory Management Software in FMCG?

In an industry as dynamic as FMCG, staying ahead of the curve isn’t just about capitalising on the fast-moving nature of the goods. It’s about adopting and implementing systems that complement this pace.

As the FMCG landscape becomes more competitive, the tools employed by businesses must evolve, leading us to the imperative of automated inventory management software.

Can you address FMCG’s Unique Challenges Through Automation?

At its core, automation is about efficiency and precision—two qualities indispensable to FMCG inventory management. With the fast turnover and perishability of goods, there’s little room for error.

Automated inventory management software, designed with the nuances of FMCG in mind, brings several game-changing benefits to the table:

- Real-time Tracking

Instead of periodic checks, businesses can monitor their inventory in real-time. This constant vigilance ensures that perishable products are sold within their shelf life and that stock levels are adjusted promptly based on sales velocity.

- Demand Forecasting

Predictive analytics, powered by historical sales data and market trends, allows businesses to anticipate demand surges or drops. Such foresight can be the difference between capitalising on peak demand seasons or being left with unsold stock.

- Efficient Reorder Points

Instead of generic reorder thresholds, automation enables businesses to set dynamic reorder points. By analysing sales trends, seasonality, and lead times, the software can suggest when and how much to reorder, minimising stockouts and overstocking.

What are the Features Tailored for the FMCG Sector?

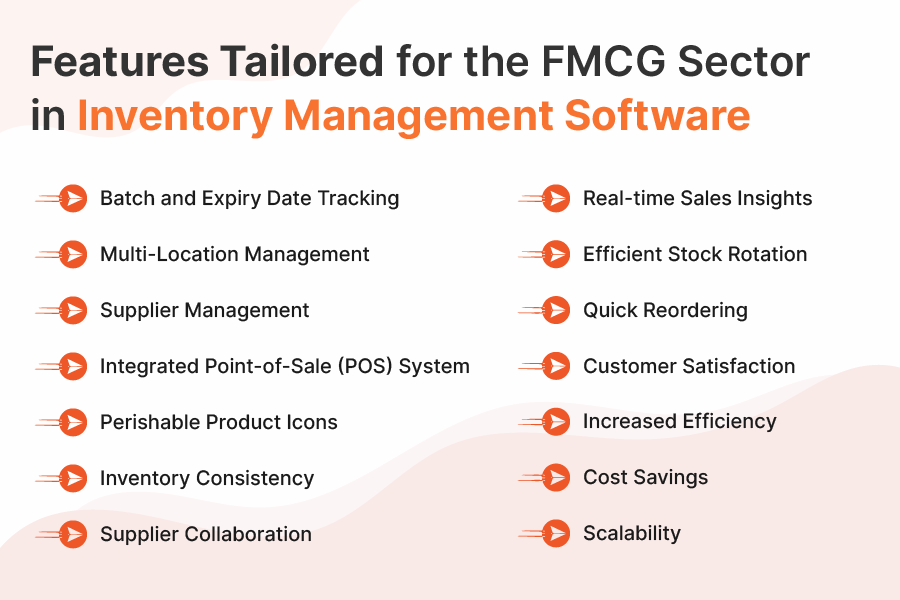

Automated inventory management software isn’t a one-size-fits-all solution. The systems most beneficial to FMCG businesses come packed with features explicitly tailored for this industry’s unique challenges:

- Batch and Expiry Date Tracking

Given the perishability of many FMCG products, having a system that can monitor batches and their respective expiry dates is invaluable. This feature helps businesses prioritise stock rotation and ensures that expired products never reach the customer.

- Multi-Location Management

Many FMCG businesses operate across multiple storage locations or retail outlets. An automated system allows for seamless integration of stock levels across these locations, ensuring consistency in inventory data.

- Supplier Management

Building strong relationships with suppliers is critical in the FMCG sector. The right software assists in tracking supplier performance, managing contracts, and facilitating quick reordering.

- Integrated Point-of-Sale (POS) System

For businesses with physical stores, integrating POS with inventory management can provide real-time sales data. Businesses can instantly update stock levels and inform reorder decisions.

What are the Key Features of Automated Inventory Management Software?

In the whirlwind pace of the FMCG sector, businesses need an arsenal of tools to ensure that their operations run smoothly. At the forefront of this arsenal is the automated inventory management software, a beacon of efficiency and precision in a landscape marked by its volatility.

Let’s delve deeper into some of its pivotal features that have revolutionised FMCG inventory management.

What is Proper Inventory Tracking?

Holistic View

One of the primary benefits is the ability to have a bird’s eye view of your entire inventory. At any given point, businesses can check which products are in stock, which are running low, and which are overstocked.

Batch and Expiry Monitoring

Especially relevant to the FMCG sector, the software allows tracking based on batches and their expiry dates. This ensures timely stock rotation and reduces wastage of perishable goods.

Insights into Sales Velocity

Real-time tracking also provides insights into which products are selling fast and which aren’t. These insights can inform decisions on promotions, discounts, and procurement strategies.

What is Demand Forecasting?

Historical Data Analysis

The software sifts through past sales data to identify patterns and trends. By understanding what sold well in previous seasons or during specific periods, businesses can better prepare for similar future scenarios.

Market Trend Integration

Beyond historical data, demand forecasting tools also integrate current market trends. This helps businesses stay aligned with consumer preferences and industry shifts.

Informed Procurement

With accurate demand forecasting, businesses can make informed decisions about procurement, ensuring they neither over-purchase nor under-purchase.

How to Reorder Points and Safety Stock Levels?

Dynamic Reorder Points

Rather than static reorder thresholds, the software analyses sales data, lead times, and other relevant factors to suggest when it’s optimal to reorder a particular product. This ensures that stock is always replenished before it runs out but without excessive overstocking.

Safety Stock Calculation

Safety stock acts as a buffer against unexpected demand surges or supply chain disruptions. The software can calculate the ideal safety stock levels based on historical sales variability and supplier reliability.

As a result, businesses are always a step ahead of unforeseen challenges.

Making the Switch — What to Consider?

Transitioning from a manual inventory management system to an automated one is akin to stepping into a new era of efficiency and accuracy. However, like any significant shift, it comes with its set of considerations.

Ensuring a smooth transition, especially in the FMCG sector where speed is paramount, demands strategic planning. Let’s unpack the critical elements businesses need to consider when making the switch.

How can you integrate with Existing Technology?

A seamless fusion of the new automated system with the existing technological infrastructure is pivotal. A few key points to ponder:

- Compatibility

Ensure the new inventory management software is compatible with your current Point-of-Sale (POS) system, Enterprise Resource Planning (ERP) system, and any other critical business software.

- Data Migration

Transitioning means moving vast amounts of data from the old system to the new. Automated inventory management software should offer easy data migration tools. Hence, it ensures that historical sales data, product information, and other essential details are transferred without hiccups.

- Unified Dashboard

Ideally, the new system should provide a unified dashboard that aggregates information from various integrated systems. This offers a consolidated view of business operations.

How is Training and Skill Development Helpful?

While automated inventory management software is designed for ease of use, there’s still a learning curve:

Staff Training

Invest in training sessions for staff members to adopt the software easily. This will make it easy to get acquainted with the software’s features and ensure there is not much resistance to technology or changes.

Continuous Learning

As software updates roll out or new features are added, it will be helpful to ensure the team is onboard with the new changes. Short, refresher courses can prove useful in this regard and will streamline business operations.

Support and Documentation

Opt for software that comes with detailed documentation, tutorials, and responsive customer support. This aids in troubleshooting and ensures that you can resolve problems quickly without affecting the business operations.

What are some Budgetary Considerations?

Making the switch is an investment, so having a clear picture of the budget is essential.

Cost-Benefit Analysis

While there will be initial costs involved in purchasing and implementing the software, weigh these against the long-term benefits. Consider the savings from reduced wastage, improved stock accuracy, and enhanced efficiency.

Scalability

As your FMCG business grows, will the software adapt? Opt for systems that offer scalability without exorbitant costs.

Hidden Costs

Be wary of any hidden costs. This includes charges for updates, additional features, or support. It’s wise to have a transparent discussion with the software provider about all potential charges.

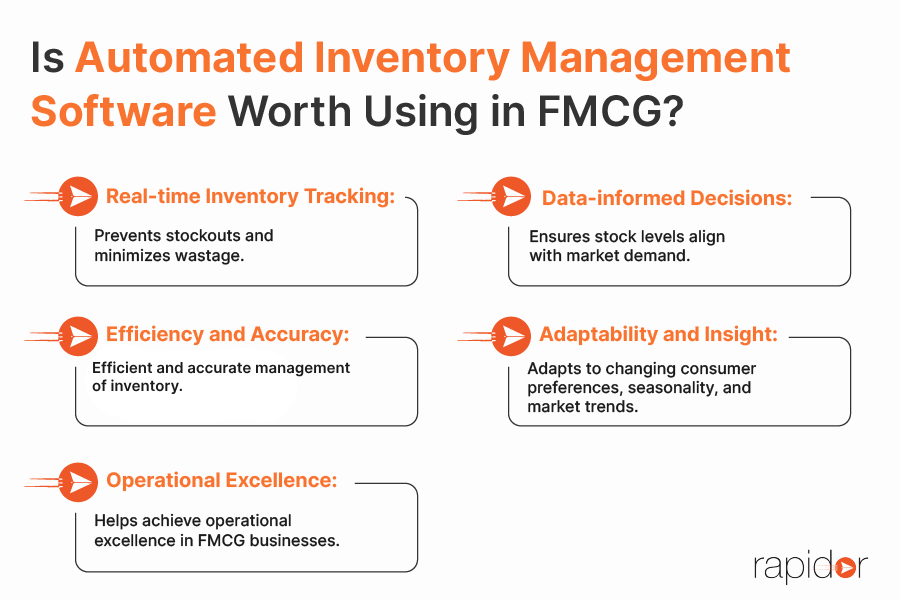

Is Automated Inventory Management Software Worth Using?

Navigating the intricate lanes of the FMCG industry, where the tempo is relentless and the margin for error minimal. Moreover, there’s a need for tools that are equally agile and precise.

As we’ve journeyed through this exploration, the transformative potential of automated inventory management software has become evident. Real-time inventory tracking ensures businesses remain proactive rather than reactive, preventing stockouts and minimising wastage.

Plus, data-informed decisions ensure stock levels always align with market demand. Also, automated systems ensure inventory management is both efficient and accurate, striking the perfect balance between demand and supply.

If there’s one constant in the FMCG sector, it’s change. Fluctuating consumer preferences, seasonality, and market trends underscore the need for a system that’s both adaptable and insightful.

Automated inventory management software rises to this challenge, offering FMCG businesses a platform that’s not just about managing stock but about unlocking operational excellence.

Take a moment to evaluate your current inventory systems. Do they meet the unique challenges of the FMCG landscape head-on? If there’s even a hint of doubt, it might be time to consider the unmatched benefits of automated solutions.